Radiographic Inspection ( X-Ray ) Services

Orange Coast Testing operates radiographic inspection laboratories, staffed with certified technicians and outfitted with the latest technical and image processing equipment to process, inspect, and certify to the highest standards a wide variety of products for the aerospace, power generation, military, nuclear, and commercial industries.

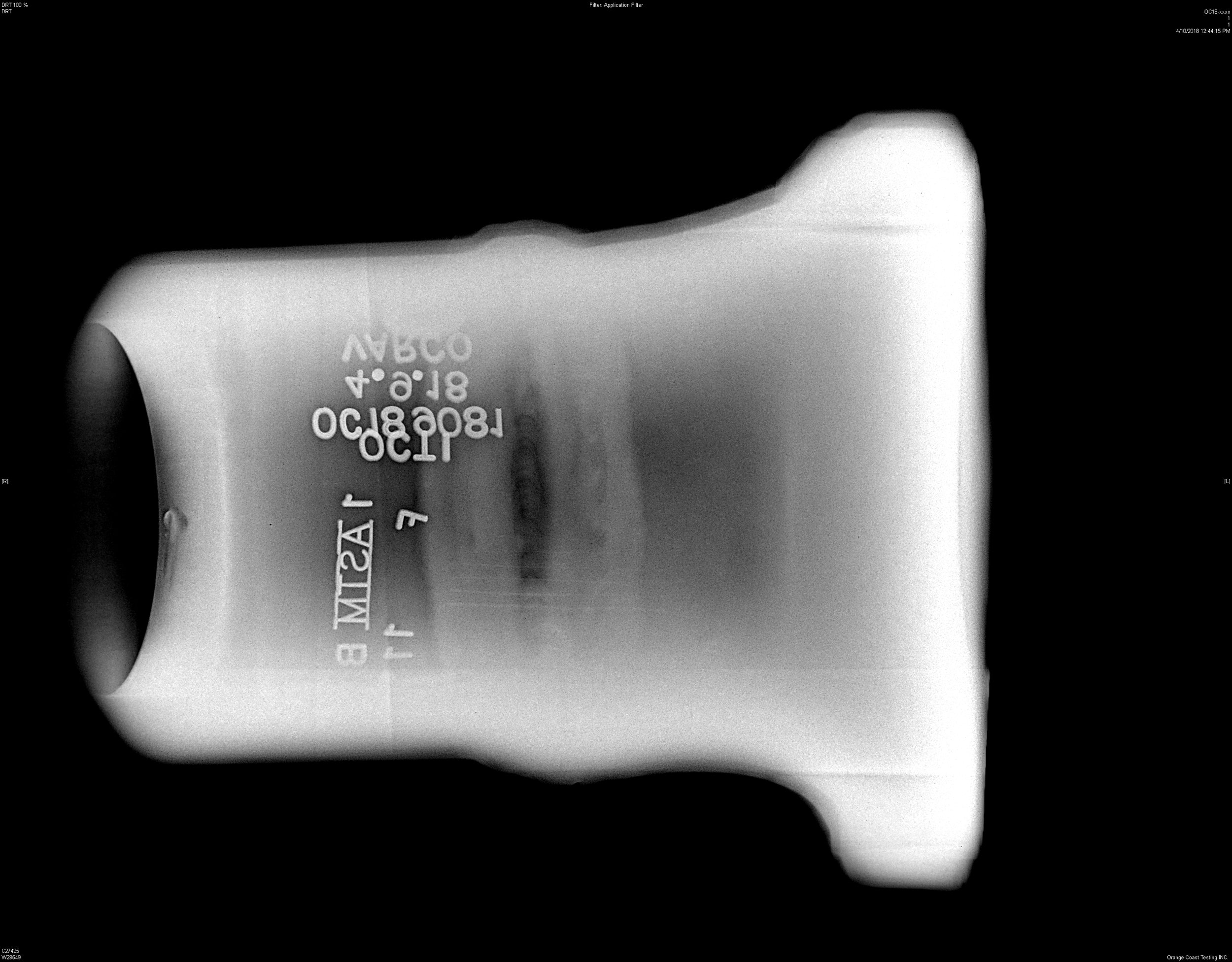

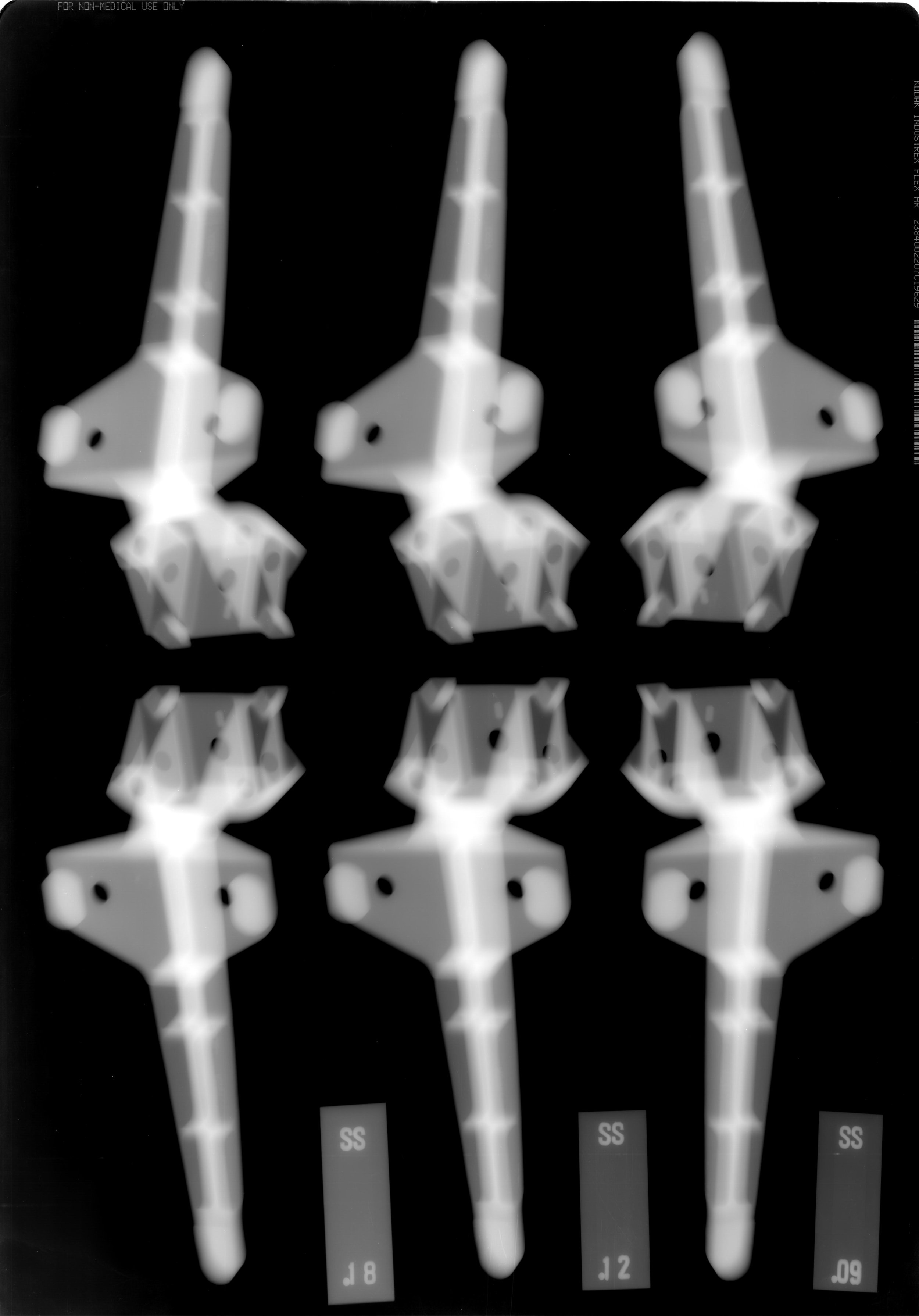

Film Radiography

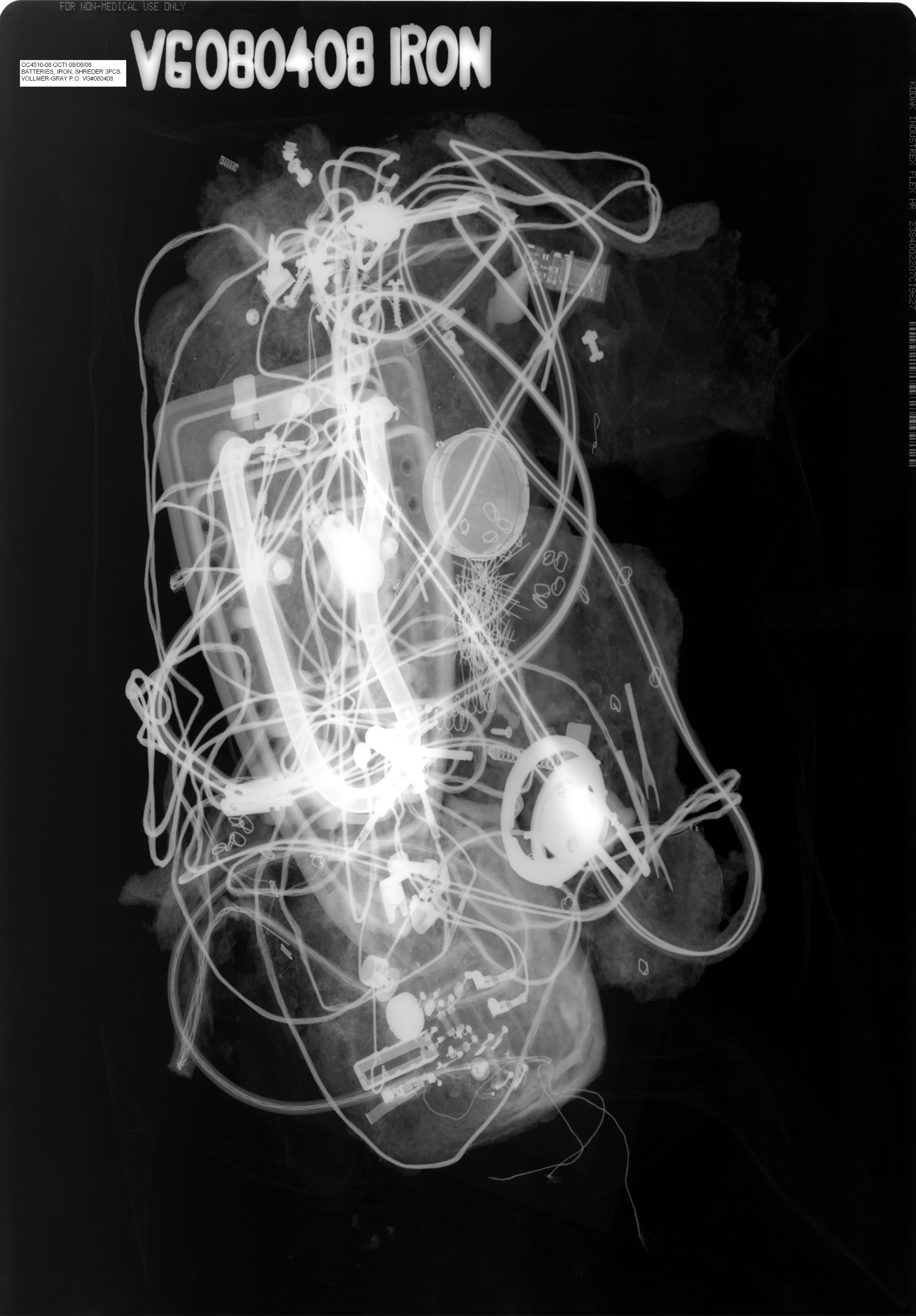

X-Ray of castings, electronics, welds, composite materials and a variety of other products is our greatest capability. Whether you require production run inspection or assistance in identifying technique capabilities in engineered prototype products, we can help. All tasks are personally supervised by an NDT level 3 examiner in Radiography. Radiography is used heavily in the aerospace industry for the detection of cracks in airframe structures and for foreign object detection. Our personnel set-up, expose, process the film and interpret the images in accordance with written records or specifications

Qualification of welds

Internal examination of piping components

Radiography can be used to provide permanent visual record of the test object on film

Radiography can reveal some discontinuities within a material

Radiography discloses fabrication errors and often indicates the need for corrective action

Radiography can be used with most materials.

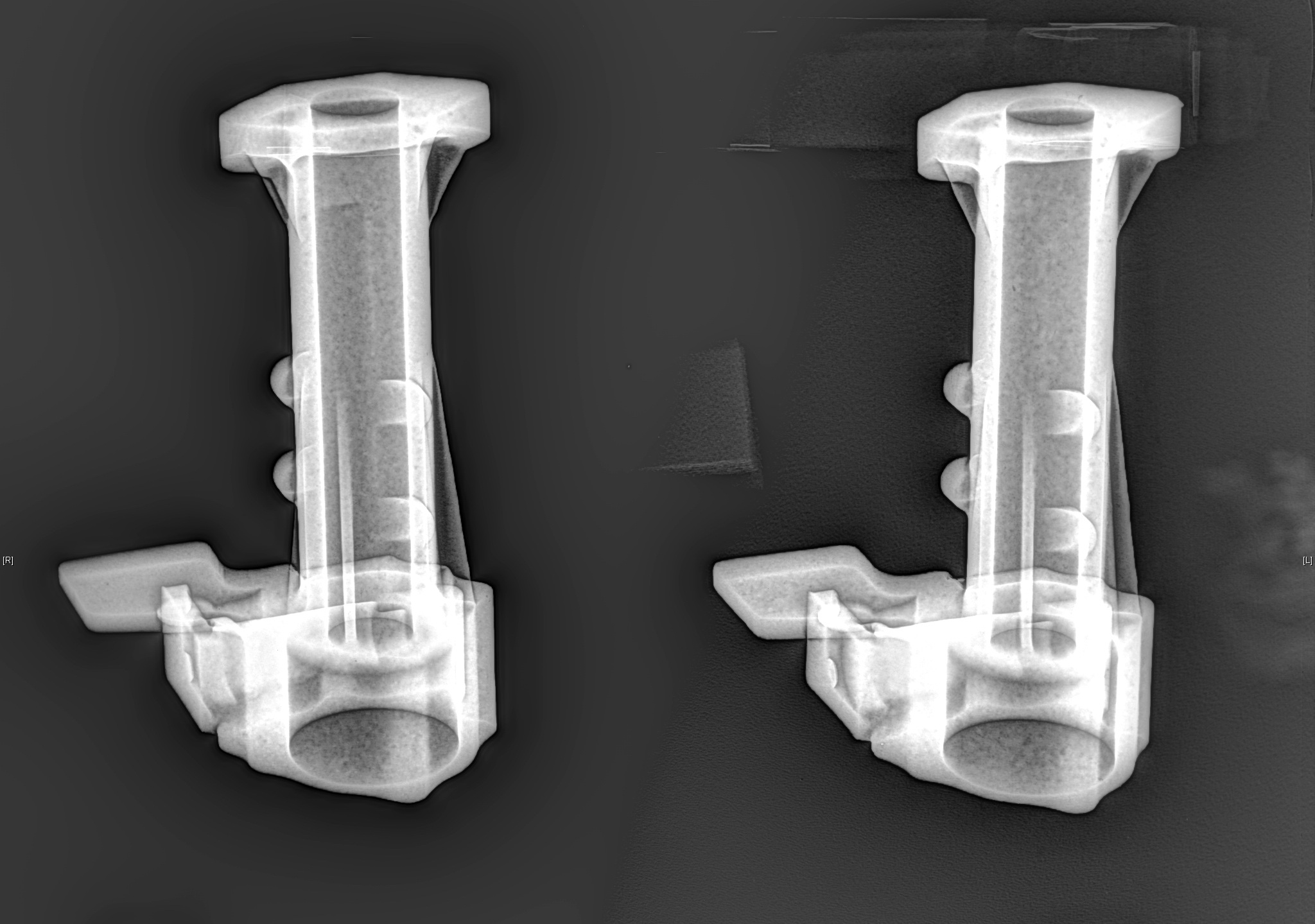

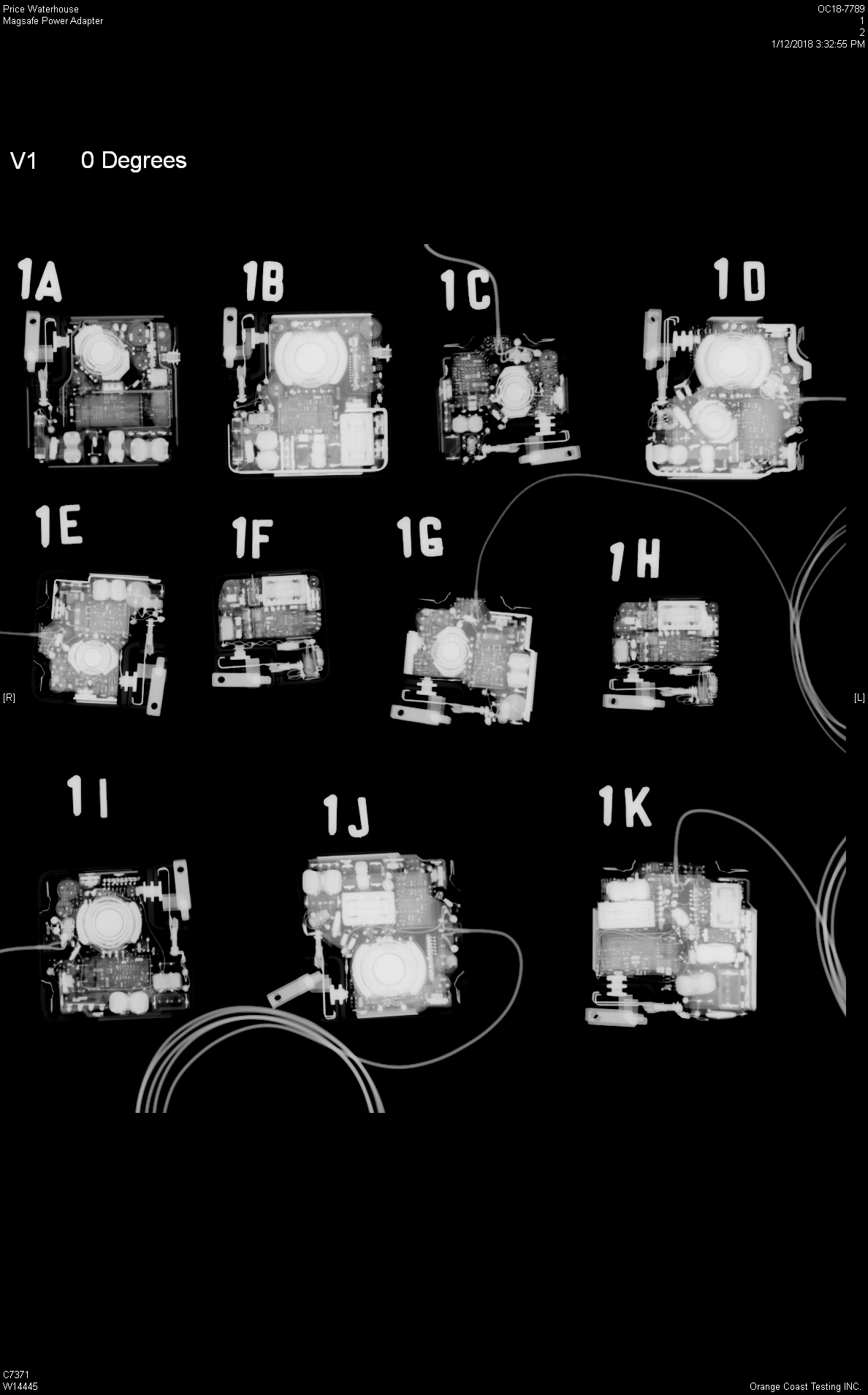

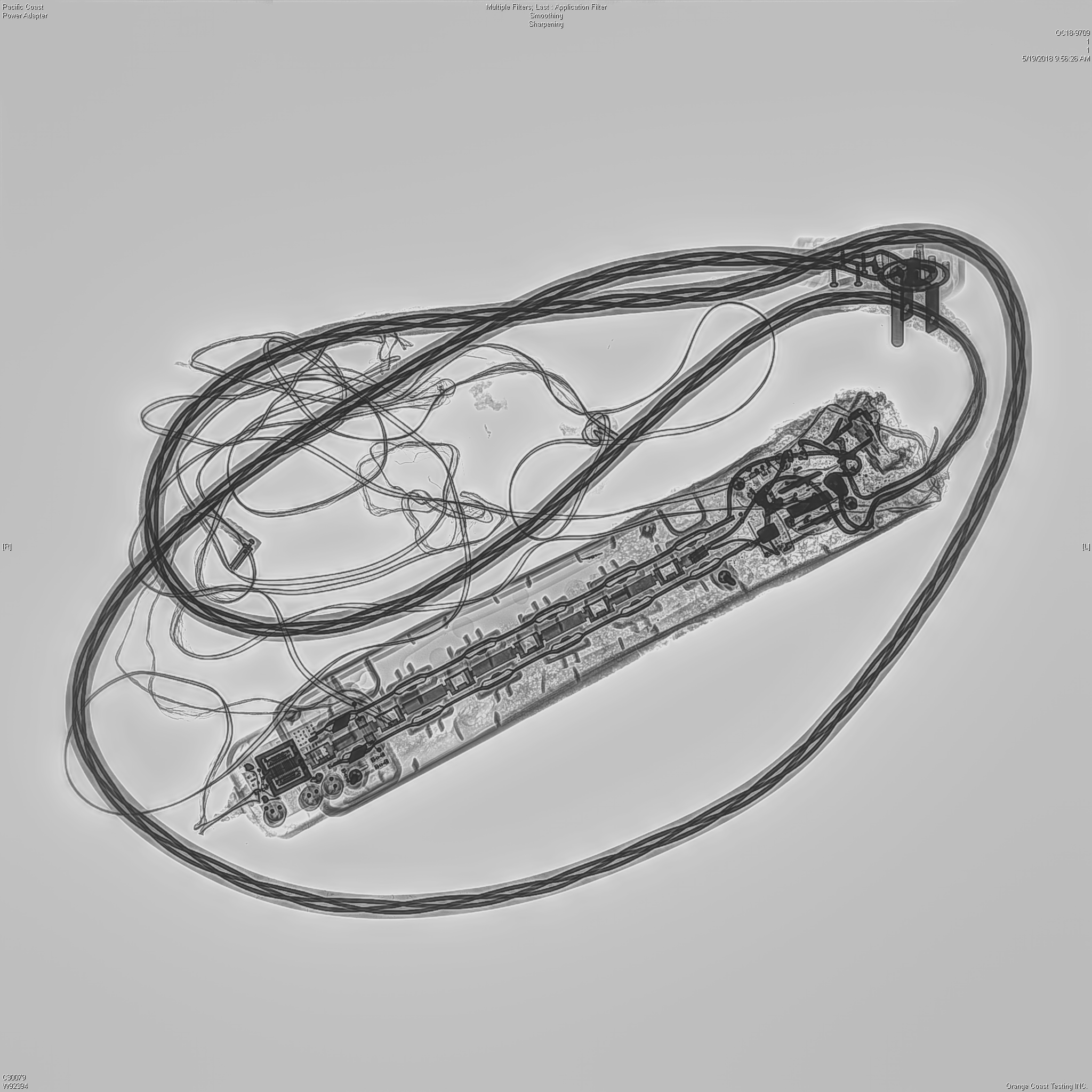

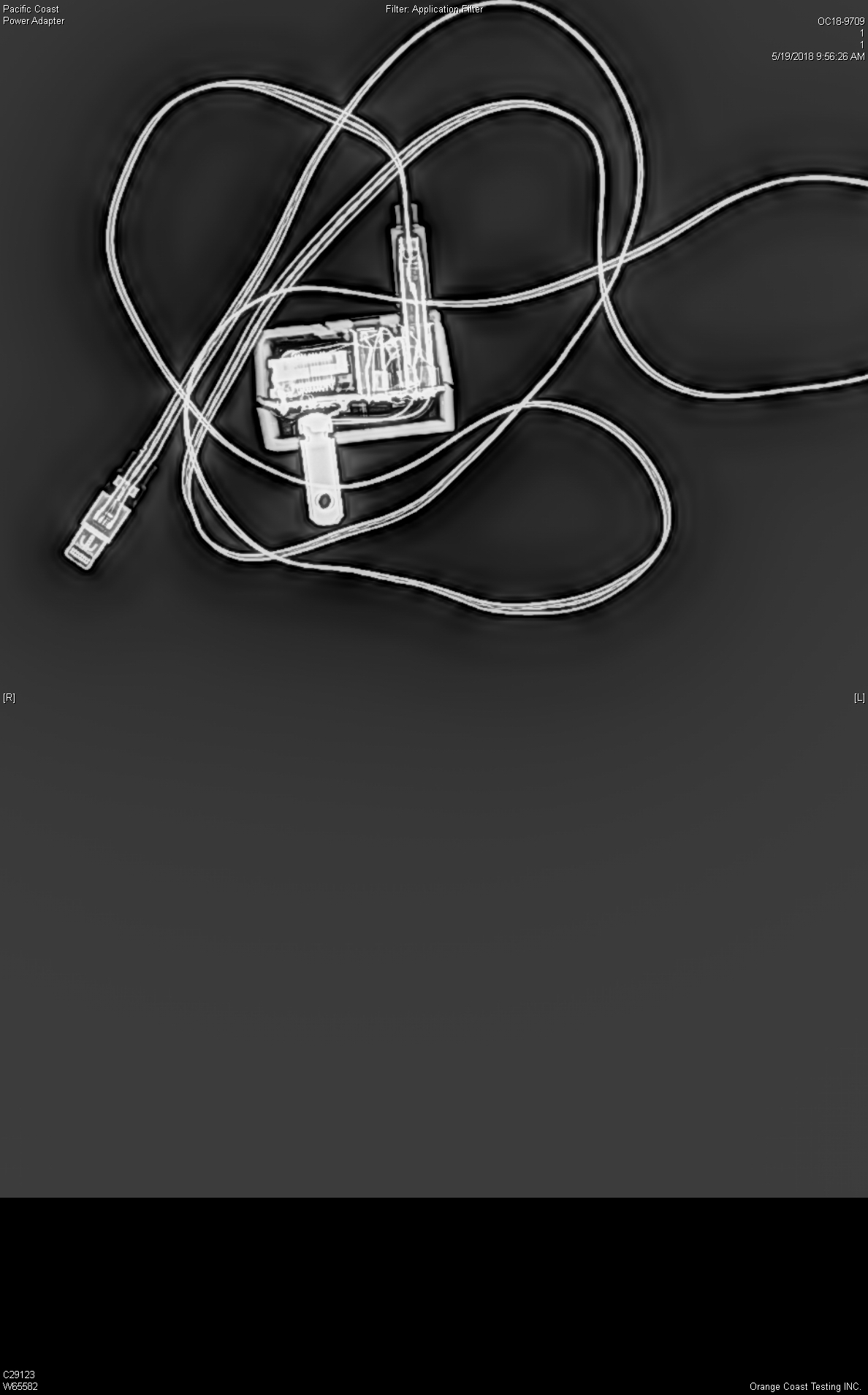

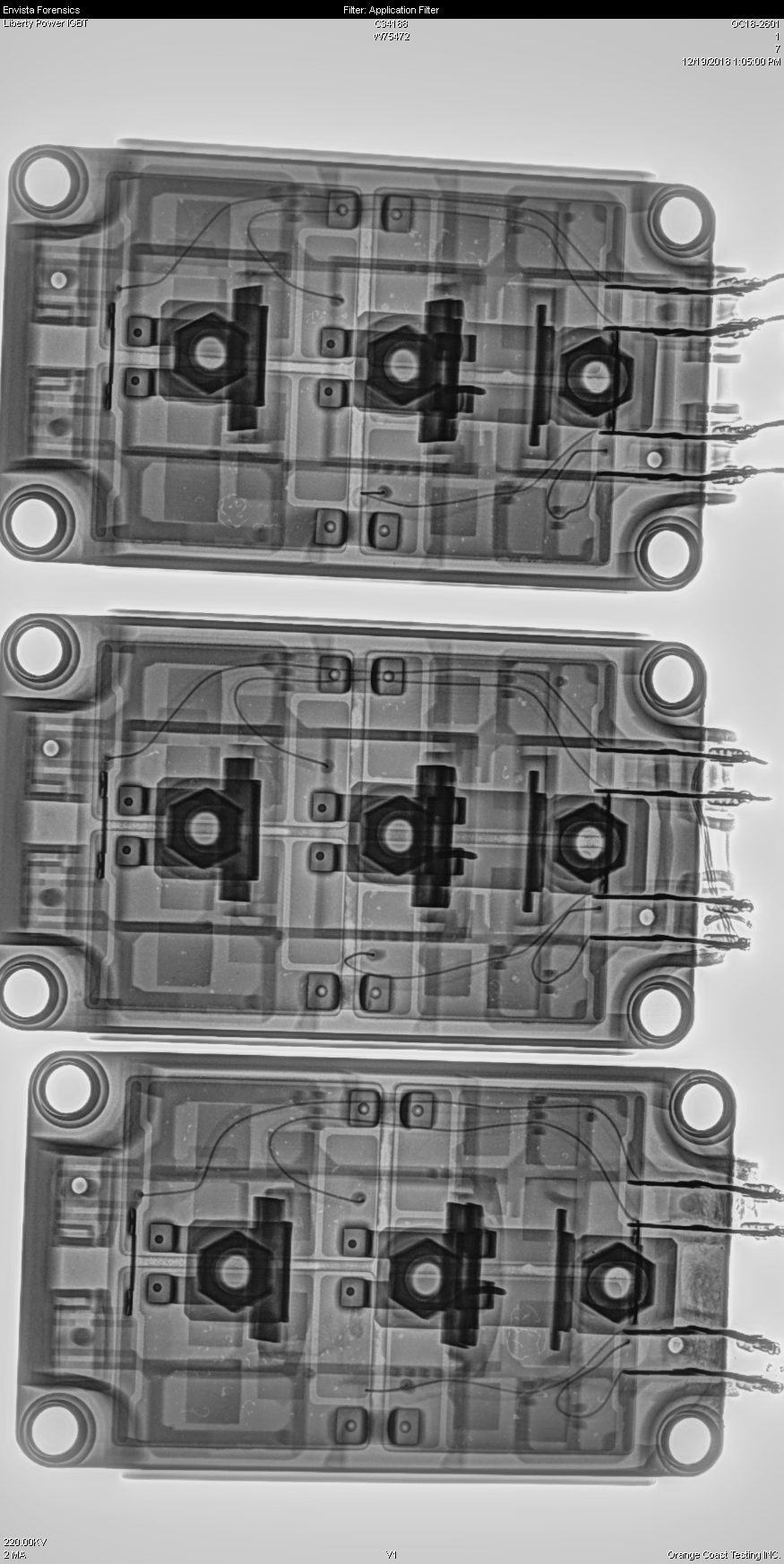

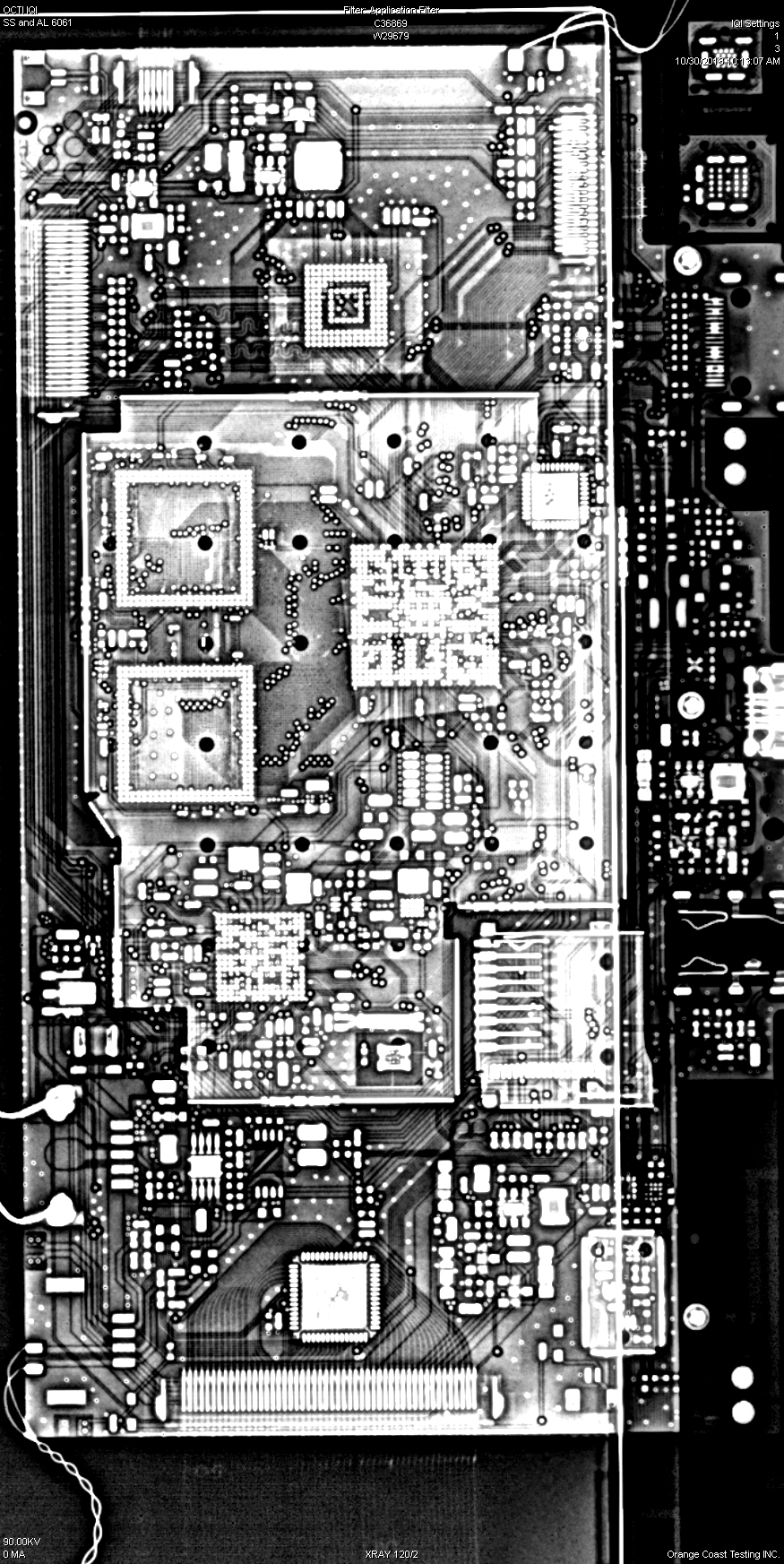

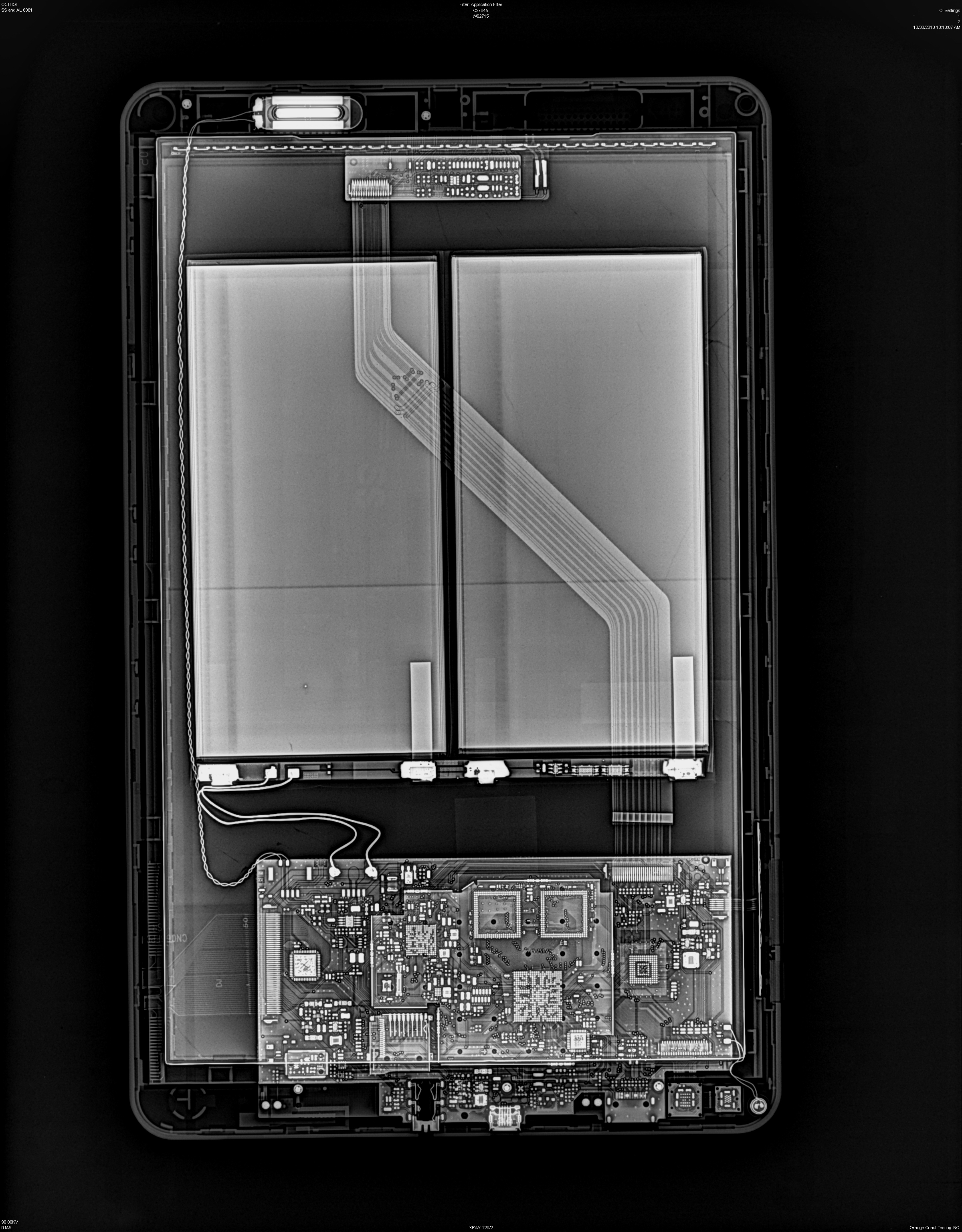

Digital Imaging

Orange Coast Testing continues to use state-of-the-art equipment for Non-Destructive Testing, At Orange Coast Testing we utilize our DXR500L Static Digital Detector Array designed for exclusive use in GE’s industrial X-ray inspection and the DXR500L is able to provide extremely high image quality in production environment. The DXR500L allows easy defect detection. Our temperature controller allows for longer shot time intervals and quick, consistent images.

Applications

Aerospace investment castings

Industrial investment castings

Wax and ceramic patterns

Burned or damaged electronics or parts

Metrology

Materials science/geology

Features and Benefits

High-resolution images for easy detection of subtle indications

Endurance™ scintillator technology for optimal image quality and lag

Temperature controlled for stable offsets over longer periods, enabling more consistent imaging and fewer calibrations

Eliminates film and reduces exposure time

Significant reduction in NDT inspection cycle time

High quality radiography at lower cost than traditional methods

Hard-copy solutions (Digitized Film)

Increased accuracy of nondestructive inspection results interpretation

Highly efficient image archiving and retrieval

Images always stored in raw un-enhanced format and may not be altered

Powerful, intuitive software for image analysis and enhancement provides increased NDT inspection accuracy and image evaluation.

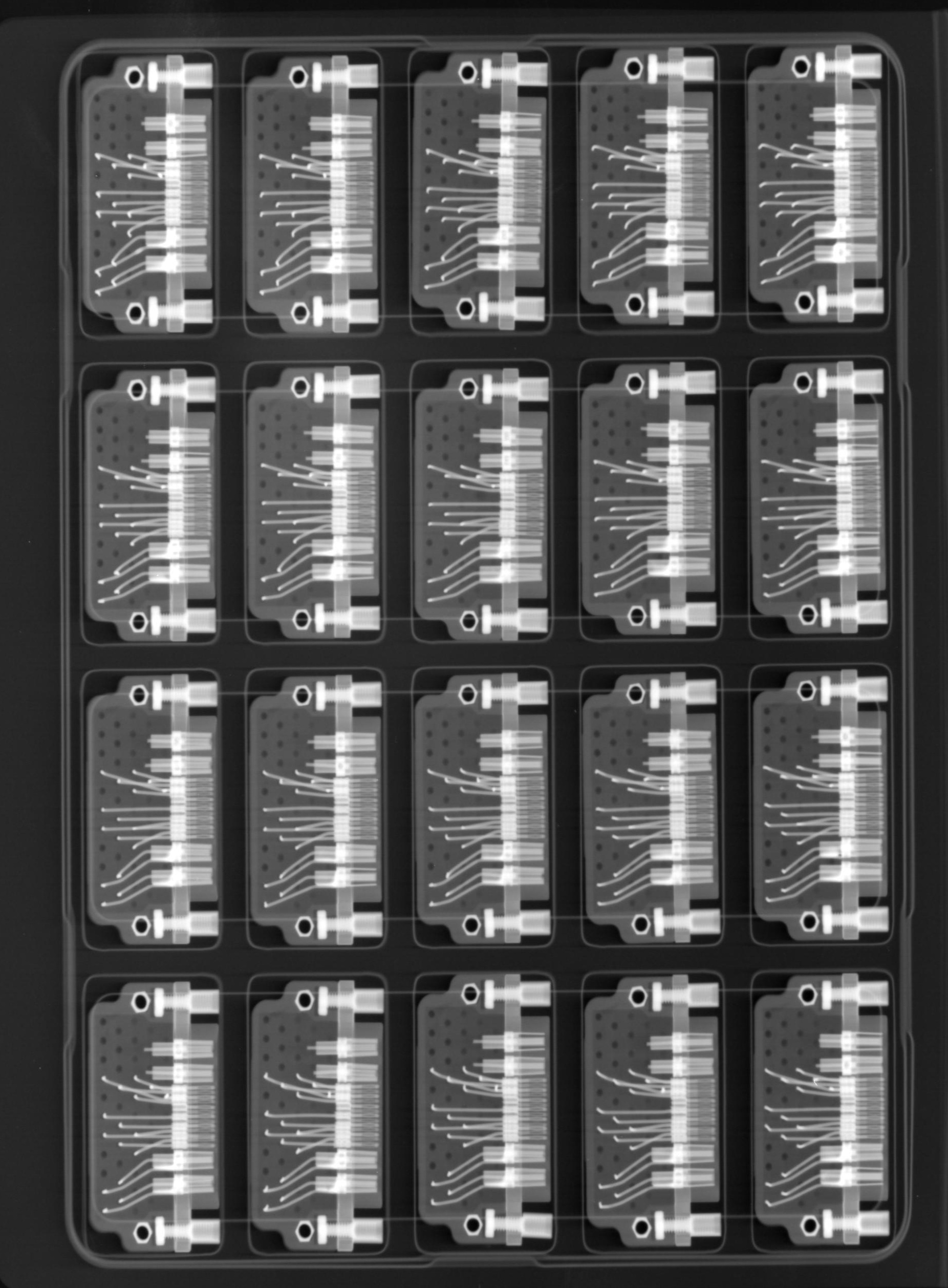

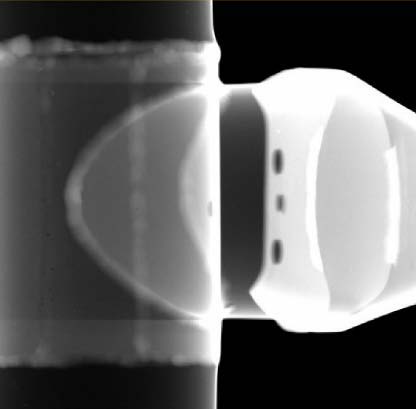

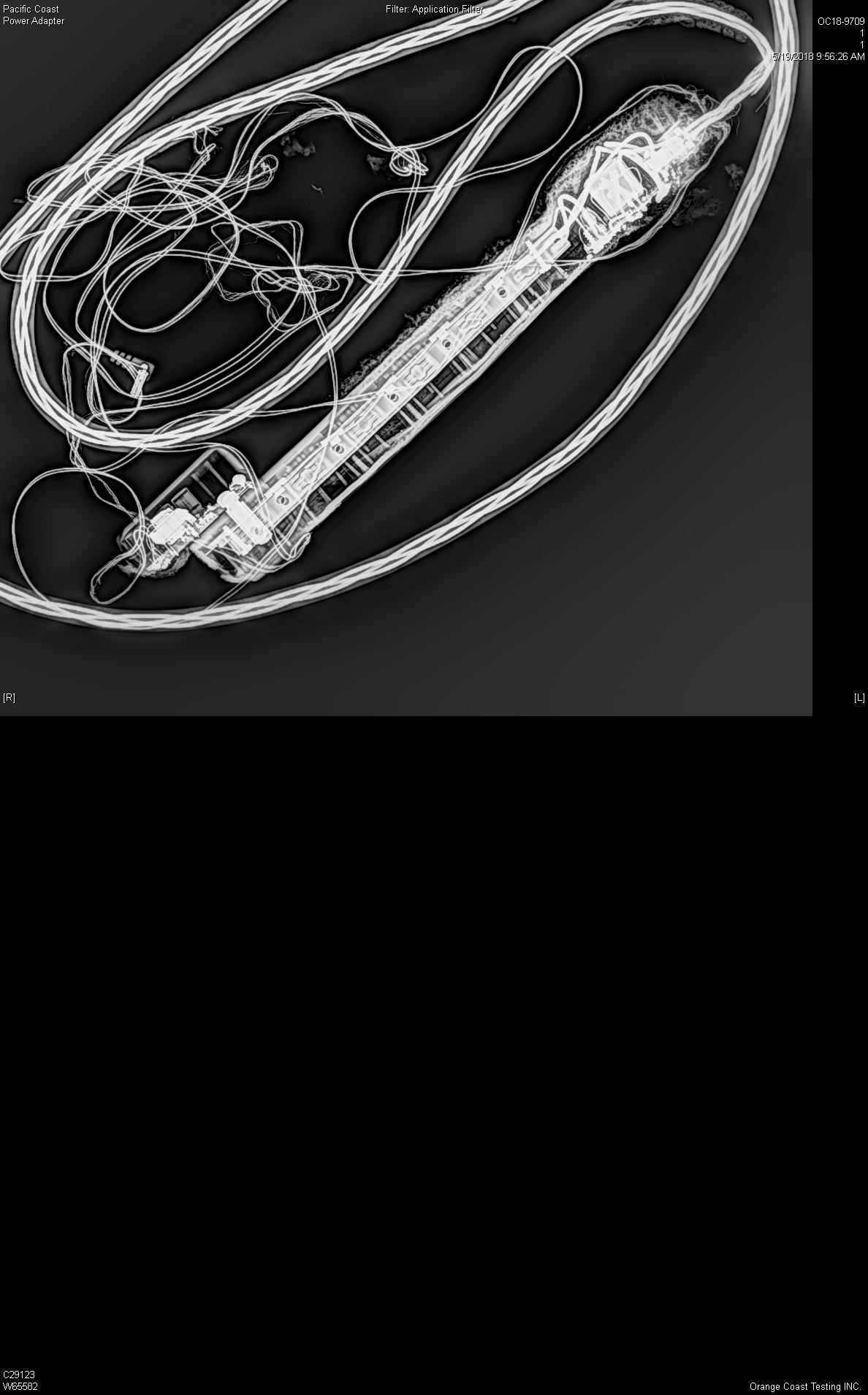

Real-Time Radiography

Utilizing a five-axis manipulator, and a constant potential x-ray system with a focal spot size of 0.06 mm, we can generate different views which can easily identify discontinuities such as broken wires in electronics, shrinkage in aluminum castings, consumer products, foreign material in food products, etc.. Permanent records are made on videotape transferred to DVD.

In addition to our real-time lab station, we have several portable systems complete with variable speed conveyors. These portable systems are ideal in high production (assembly line) situations, when products require rapid evaluation. Often used for Quality Control screening of Consumer Products.

Radiographic Advantages

Radiography can be used with most materials

Radiography can be used to provide permanent visual record of the test object on film or a digital record for subsequent display on a computer monitor

Radiography can reveal some discontinuities within a material

Radiography discloses fabrication errors and often indicates the need for corrective action