Metallurgical Testing

Metallurgical testing is used in virtually every industry and covers a wide range of services, from grain size analysis to fractography. Our engaged experts can identify material type, defects and processing errors using a variety of techniques and equipment. Manufacturers are employing better technology to bring innovative materials to the market. While many traditional metallurgical testing methods used for evaluating metals remain the same, metallurgists are facing more challenges than ever before. Metallurgical testing focuses on quantifying the properties of metals in conjunction with mechanical testing and chemical analysis. Metallography is frequently used to determine material type, grade or grain size, and to provide certifications for new material or mixed batches, microstructure analysis and failure analysis.

Our metallurgical testing capabilities

OCTI’s metallurgical testing laboratories use the required expertise and technology to test both traditional metals and advanced alloys. Many of our metallurgical test methods can be done on-site, or alongside our experts in one of our state-of-the-art labs.

Our trained metallurgists are experienced in:

Corrosion

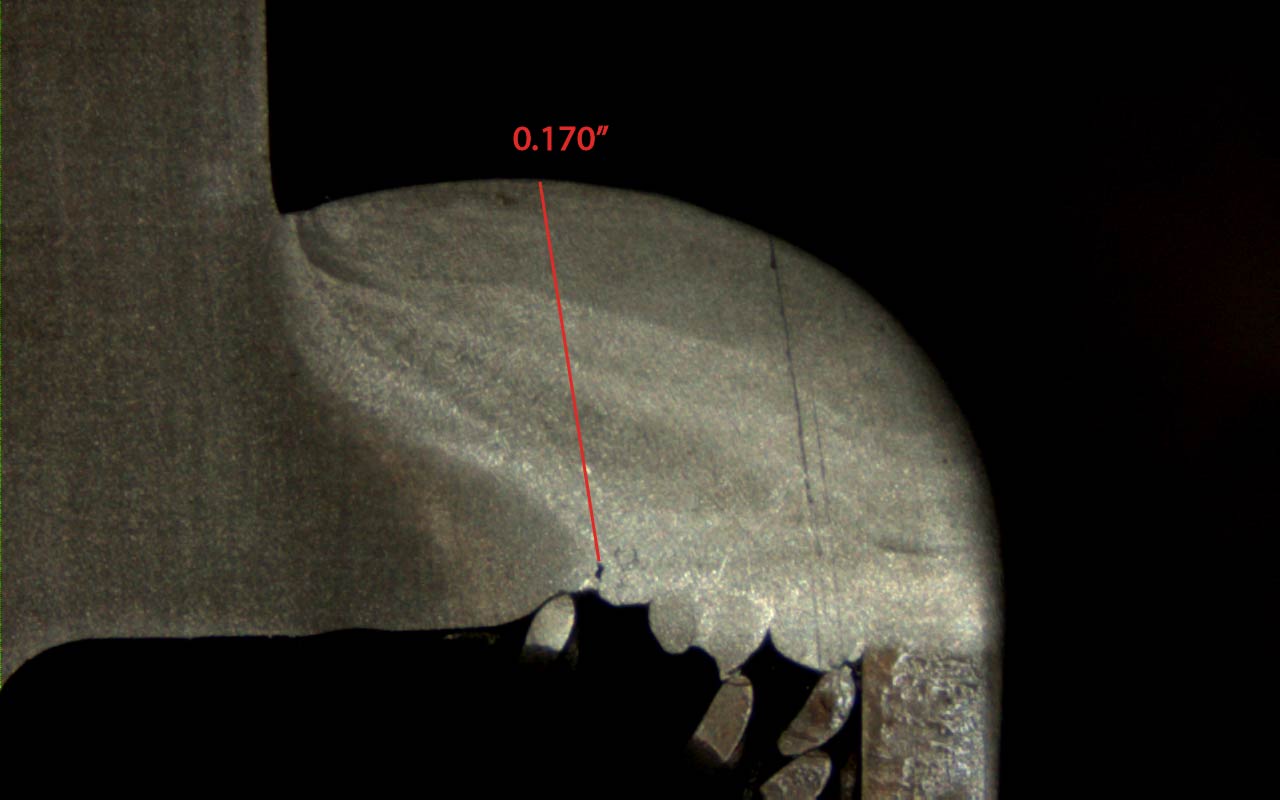

Fractography

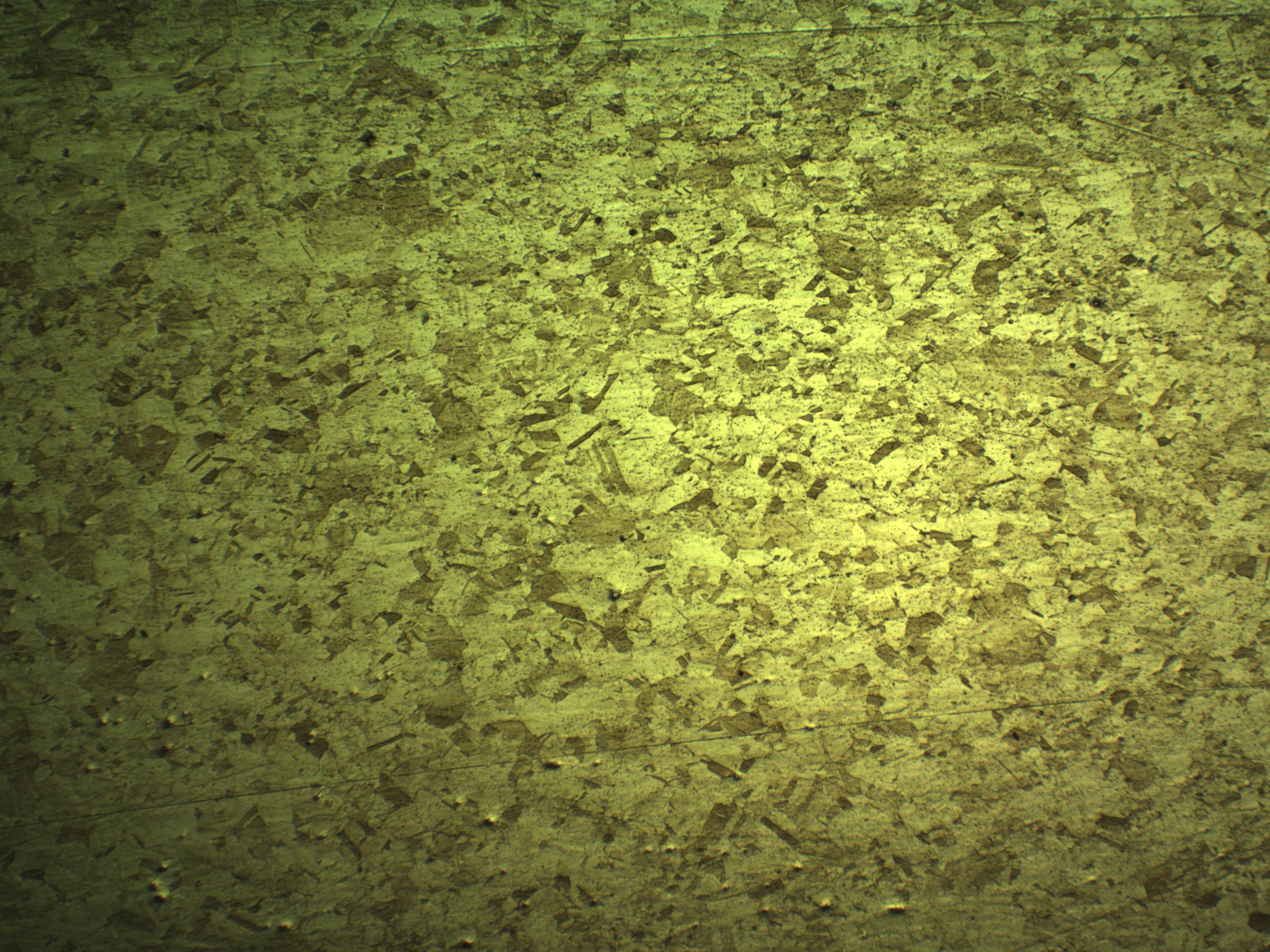

Material identification

Macroscopic evaluation

Microscopic evaluation

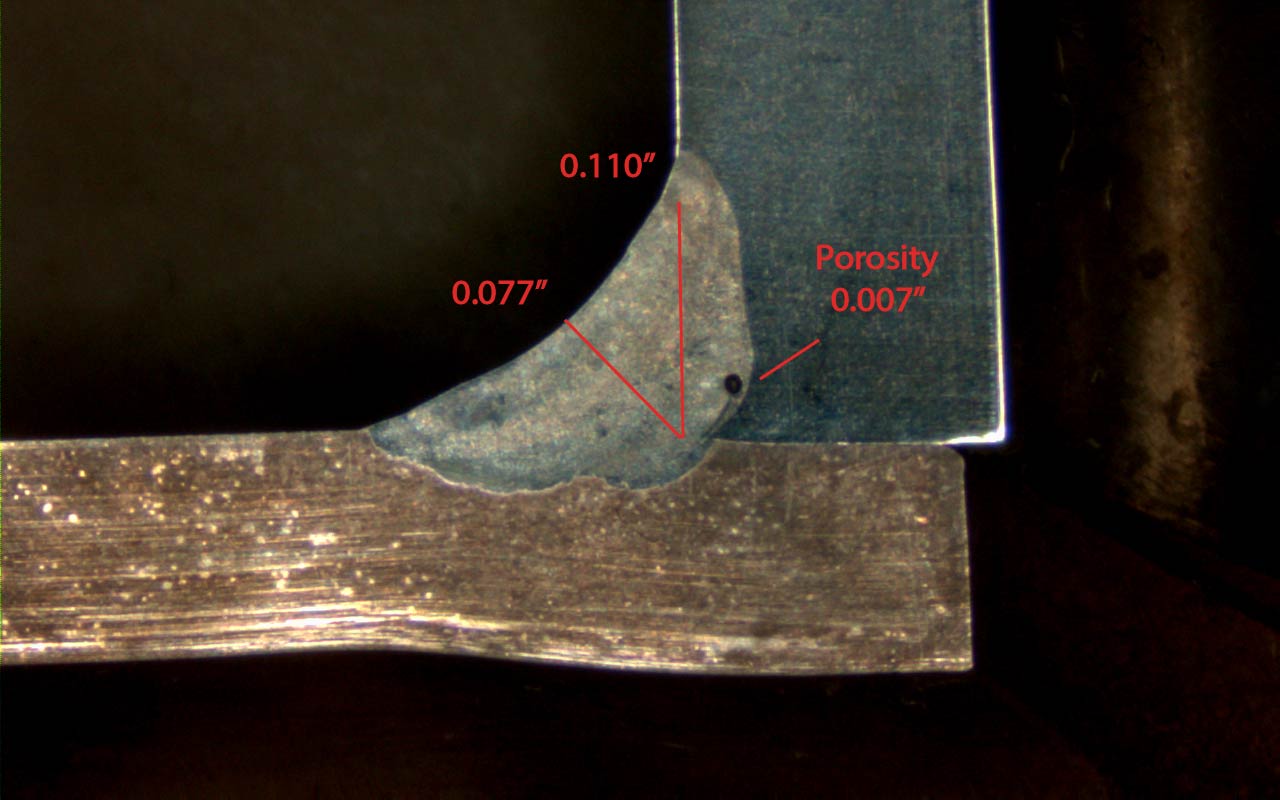

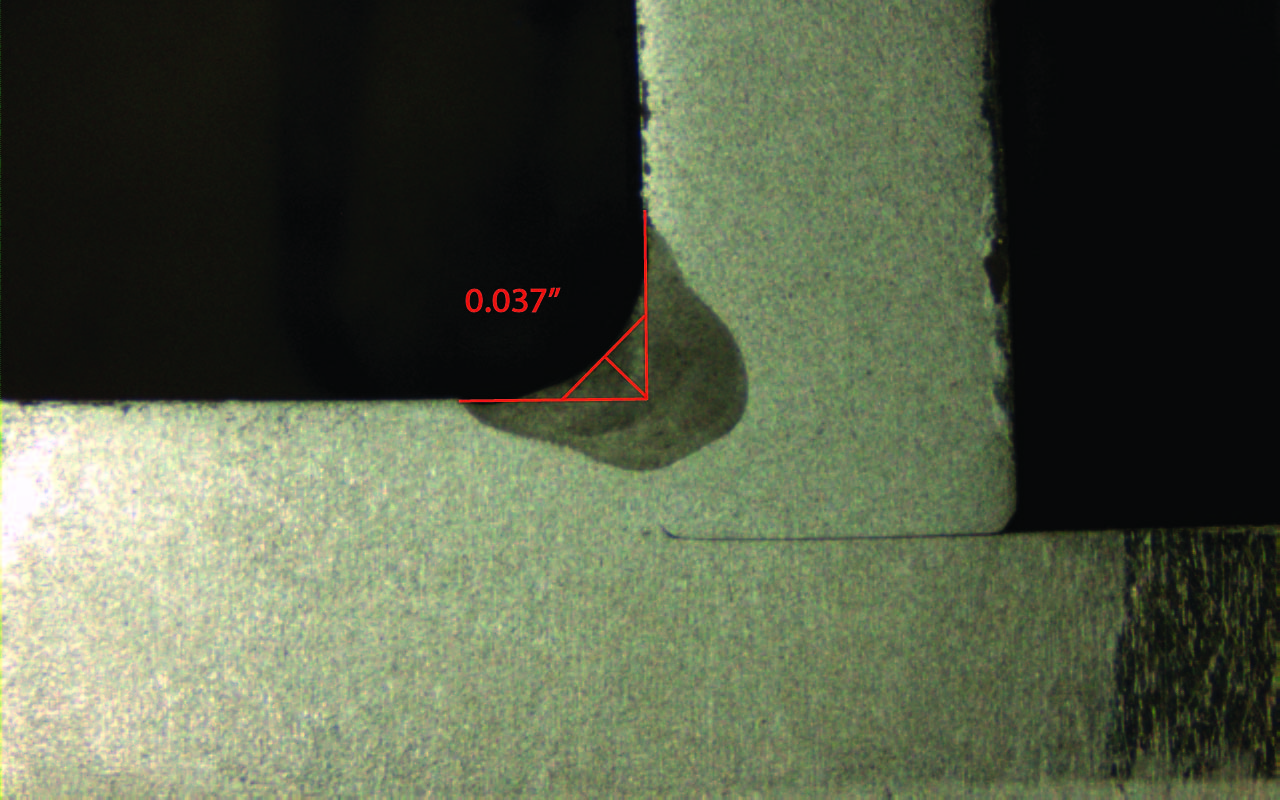

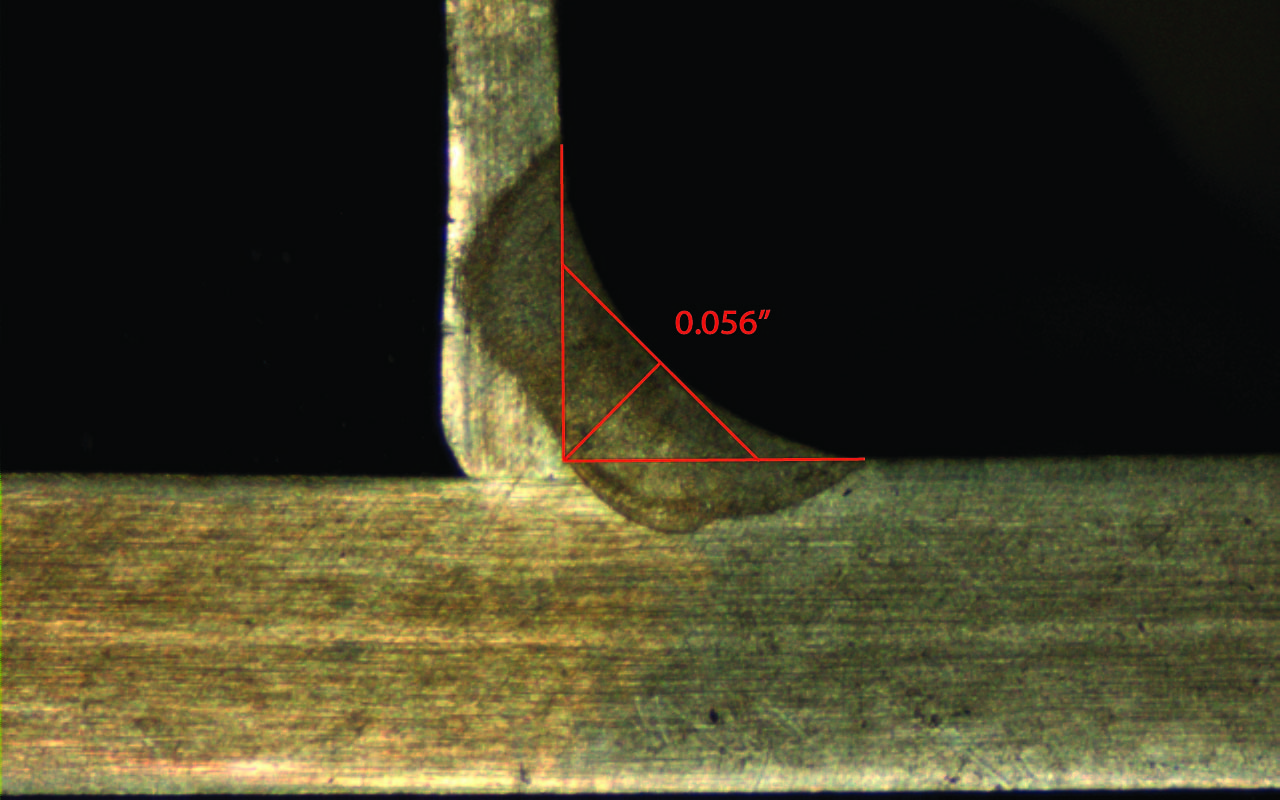

Weld Testing

With metallurgical testing, we can assist with any project, no matter how large. For more information about our metallurgical testing services or to request a quote, contact us today.