As an industry leader in Nondestructive and Destructive testing, Orange Coast Testing is proud to be the name that people turn to when their application requires testing with honesty, integrity and a superior attention to detail. For over 3 decades, OCTI has provided quality NDT inspection services and destructive services to a wide variety of industries, including critical fields such as aerospace and defense. Our reputation for detail and precision is further supported by our extensive accreditation and certifications, including NADCAP and ISO. In addition to our outstanding services, our company is supported by a philosophy that quality with exceptional services is our standard.

To provide further value, we offer our extensive selection of testing services with competitive pricing and extremely fast turnaround, as well as additional services, such as consultation, training, and on-site testing. For quality assurance with a proven track record and superior customer care, give us a call today.

Our Services

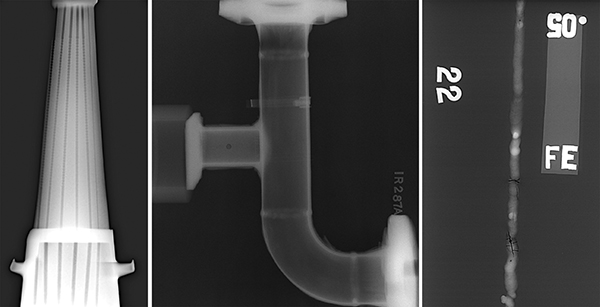

Radiographic Inspection

Radiographic inspection (RT) is performed using a radioactive isotope or an x-ray tube in order to create an image on a film or in a digital format. This non-destructive testing (NDT) method is a volumetric inspection in which defects that are not open to the surface can be detected that may not otherwise be detectable. A vast array of material and products can be examined for discontinuities using radiographic inspection, ranging from tiny electronic components to large vessels.

X-Ray of castings, electronics, welds, composite materials and a variety of other products is our greatest capability.

Visual Inspection

Even with sophisticated measuring and imaging equipment, visual inspection is still a useful, relevant tool for a range of applications. Our Engaged Experts are trained to look for defects, inconsistencies, and characteristic patterns in materials, equipment and structures, helping you ensure quality and uniformity in your products and processes.

Eddy Current

Eddy current testing is an efficient and precise non destructive test method. This type of inspection is particularly helpful to evaluate heat exchangers and aircraft parts and components.

Discontinuities are detected with custom made ET probes. EDM notched calibration standards per alloy/temper are used for known defect standards.

Liquid Penetrant Inspection

Liquid penetrant inspection (LPI), or dye penetrant inspection, is a reliable, efficient, and cost-effective method for detecting surface flaws of welds, castings, and other components that cannot be destroyed. LPI is a portable surface inspection method, allowing our Engaged Experts to conduct comprehensive onsite penetrant inspection.

Visible Dye and Flourescent Penetrant Inspections are utilized. Welds, castings, inservice fatigue crack detection and (with pre-penetrant etch) machined parts are processed.

Pressure Testing

Pressure Testing is a non-destructive test performed to ensure the integrity of the pressure shell on new pressure equipment, or on previously installed pressure and piping equipment that has undergone an alteration or repair to its boundary(s). Pressure testing is required by most piping codes to verify that a new, modified, or repaired piping system is capable of safely withstanding its rated pressure and is leak tight. Air, Dry-Nitrogen, oil and water are mediums used for leak and proof pressure testing.

Positive Material ID

Orange Coast Testing uses state-of-the-art equipment to perform chemical analysis of ferrous and non-ferrous materials. Either in our lab or at your site we will determine the exact chemistry of your material and, in most cases, tell you the specification and grade of the material.

Positive material identification (PMI) is a fast and non-destructive method for verifying the chemical composition of metals and alloys. Portable and cost-effective, PMI can be performed in one of our state-of-the-art labs, or in the field.

Magnetic Particle Inspection

Magnetic particle inspection (MPI) is a non destructive test (NDT) method used to check for surface and near-surface discontinuities in ferrous materials. Our magnetic particle testing is performed on-site at our state-of-the-art laboratory.

Wet Fluorescent Magnetic Particle Inspection is performed usimg a 6,000 Amp (FWDC, 3 Phase) stationary unit that can test parts up to 12 ft in length.

Destructive Testing

In destructive testing (or destructive physical analysis, DPA) tests are carried out to the specimen's failure, in order to understand a specimen's performance or material behavior under different loads. These tests are generally much easier to carry out, yield more information, and are easier to interpret than nondestructive testing. Destructive testing is most suitable, and economic, for objects which will be mass-produced, as the cost of destroying a small number of specimens is negligible.

Calibration Services

OCTI provides professional calibration services for a wide range of meters, gauges, and other NDT equipment used in various industries. Implementing a scheduled calibration program for your company’s testing equipment ensures that your technology continues to operate according to manufacturer standards and provides consistent and accurate data when evaluating the quality and safety of a product or machine component.

OCTI operates in compliance with all National Institute of Standards and Technology (NIST) and ISO-9000 standards; our calibration materials and standards are traceable to national standards and other recognized national calibration laboratories.